Beam Installation Options when Removing a Load Bearing Wall

When contemplating a wall removal renovation project, one of the pivotal decisions involves the selection and design of beams. The choice of beam can significantly influence both the aesthetics and functionality of the renovated space. Cost is a large factor in this decision. A good structural engineer should be able to create a design that minimises construction costs and maximizes the appeal of the renovation. Here are some typical installations when removing a load bearing wall and replacing it with a structural beam.

Dropped Beam: The Standard

Photos: Dropped beam installation with dimensional lumber used on the left and LVL (Laminated Veneer Lumber) used on the right.

Dropped beams, typically constructed from dimensional lumber, offer a timeless and versatile option for homeowners seeking a classic aesthetic. Whether you're leaning towards a vintage touch or a blend of old and new, dropped beams can seamlessly fit into various design visions.

Pros:

Simpler Installation: Dropped beams are often easier and quicker to install since they don't require integration within existing ceiling joists.

Cost-Effective: Typically, this method can be less expensive due to the reduced labour and modifications needed.

Design Opportunities: The visible beam can be used as a design feature, allowing for embellishments like coffered ceilings or decorative mouldings.

Cons:

Reduced Ceiling Height: The beam sits below the ceiling line, which can make the room feel shorter and less open.

Potential Aesthetic Disruption: If not integrated well into the room's design, it can stand out and disrupt the visual flow of the space.

Flush Beam Installation: Modern Engineering Meets Design

Photos: Flush installation of a LVL (Laminated Veneer Lumber) beam done in Burlington, Ontario.

LVL (Laminated Veneer Lumber) flush beams are where cutting-edge engineering intersects with minimalist aesthetics. Designed to integrate seamlessly with the ceiling, they promise robust support without overshadowing the room's visual appeal. Such beams bolster the expansive feel of interiors, making them an ideal choice for those seeking a blend of strength and style.

Pros:

Seamless Aesthetics: The beam is integrated within the ceiling, offering a clean and uninterrupted ceiling line.

Maximized Ceiling Height: This method retains the original ceiling height, making rooms feel more spacious.

Versatility: Suitable for both modern and traditional interiors due to its inconspicuous nature.

Cons:

Complex Installation: Requires careful alignment with existing joists and potentially more structural adjustments.

Potential Additional Costs: Might necessitate modifications to existing HVAC or electrical systems, leading to increased renovation expenses.

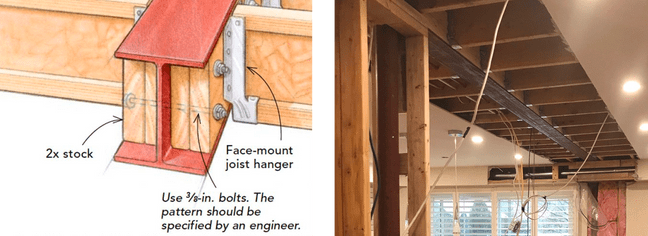

Packed Steel I-Beam: The Industrial Elegance

Photos: A steel I-beam is used to achieve a flush design. The beam is ‘packed’ with lumber on either side to allow for easy attachment of the existing ceiling joists via hangers. This is a wall removal renovation in Oakville, Ontario.

For those intrigued by industrial or minimalist aesthetics, packed steel I-beams offer a mix of resilience and refined aesthetics. These beams, envisioned to be flush with their surroundings, exude an aura of structural prowess combined with design simplicity.

Pros:

High Strength: Steel I-beams provide superior load-bearing capacity, making them ideal for larger spans or areas with significant structural demands.

Flush Design: Steel is typically the only option to get a flush design when there are bedroom about the proposed opening. Lumber is too large to fit inside the joist cavity.

Cons:

Cost: Labour and material costs are the largest drawback to making this the default option. For larger spans it is often the only viable option.

Weight: Steel beams are considerably heavier than wooden counterparts, which might require additional supports or reinforcements during installation. A typical beam will approach 600-900 lbs, requiring the use of hoists to install.

Contractor Skill: There are many contractors in Ontario that are not comfortable working with steel and prefer to work with LVLs or dimensional lumber. Getting quotes specifically from structural contractors is a good idea.

The Construction Process

The most important step to take is to hire a contractor with experience. For structural work on your home, you want peace-of-mind. Some of the main steps in the process are summarized below.

Safety and Design: Even before the installation begins, it's crucial to ensure that designs allow contractors to establish temporary supports for safety during the renovation process.

Beam Sizing and Design: Collaborate closely with experts to determine the optimal beam design based on structural requirements and aesthetic preferences.

Flush Beam Considerations: Designs should provide guidance on the feasibility of flush beams, considering factors like HVAC/electrical adjustments and the overall look of the renovated space.

Understanding Load Transference: It's essential to emphasize the importance of beams having adequate support, ensuring the loads are transferred effectively to the foundation.

Photos: A packed steel I-beam is put into place in Oakville, Ontario after the load bearing wall has been removed by the great team at Cedar Row Construction (https://www.cedarrow.ca/).

Typical Install - Packed Steel I-beam

Wall removal renovations can transform a space, creating openness and a sense of flow. However, understanding the technical aspects, like beam design, is crucial for a successful project. It's always beneficial to be informed and collaborate with experts to ensure the renovation aligns with both structural requirements and design aspirations.

Photos: A renovation in Hamilton, Ontario done by the skilled team at Cipriano Construction (https://ciprianoconstructioninc.com/).